3D Scanning For Revese Engineering

18th Oct 2021

Kiden Design

Kiden Design is a company that serves customers with creativity and design in the 3D field. They are mainly engaged in the promotion of 3D solutions, rapid prototyping, design and development.

Kiden Design´s project showcases how convenient and efficient the Reverse Engineering workflow with the EinScan Pro HD can be. The 3D scanning data and software is not limited to prescribed processing softwares, but open, so that customers can use the processing software they are used to. In this case, the 3D scanning data of a pipe were used for reverse engineering in NX. A great showcase of the flexibility and versatility of the EinScan Pro HD 3D scanner.

Check out the EinScan Pro HD video to discover the full workflow process!

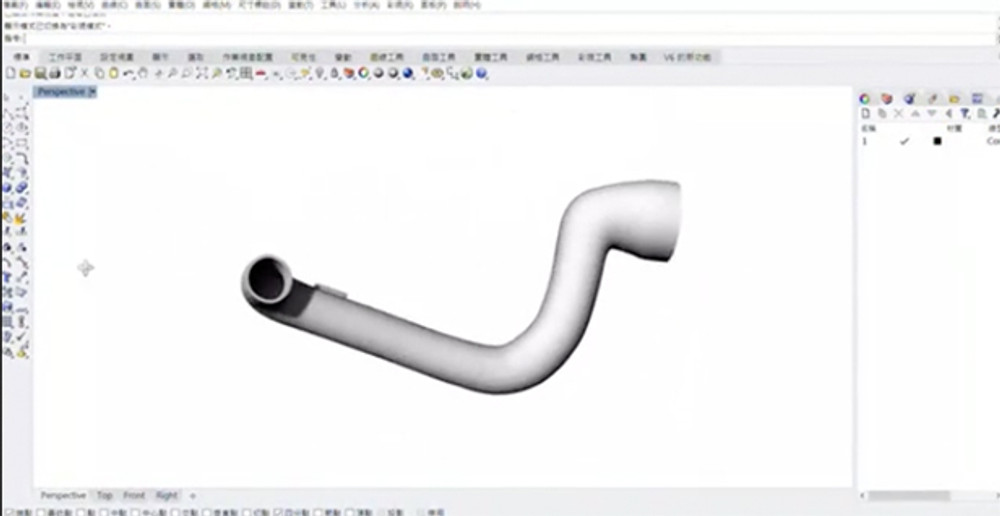

3D Scanning

With the help of the EinScan Pro HD 3D scanner, the accurate data of the original pipe can be captured authentically.

Front and back sides of the pipe can be aligned in the software and then stitched together to a complete model.

Reverse Engineering

The 3D scanning data is imported into NX for complete reverse engineering and optimization of the pipe.

3D Printing

Finally, the adjusted model manufactured into a real object with a 3D printer to verify the optimization effect.