3D Scanning vs. 3D Printing: Difference Explained

11th Jul 2025

Let’s be real, 3D tech sounds futuristic no matter how many times we hear about it.

Whether you're deep in the weeds of product design or just curious how someone scans a shoe and ends up printing a prototype that looks exactly like it, there’s something undeniably cool about it all.

But even though “3D scanning” and “3D printing” often get lumped together in casual conversation, they’re not interchangeable. They’re different beasts altogether.

And knowing the difference between the two? That’s the first step toward actually using them smartly.

So, let’s break it down - 3D scanning vs 3D printing. What’s what? Why does it matter? And how do you decide which one’s right for your workflow?

Wait—So What Is 3D Scanning?

Picture this: you've got a real-world object in front of you—say, an antique gear part, a sculpture, or even a human face (creepy or cool, you decide).

You want to turn that into a digital 3D model. That’s where 3D scanning comes in. It captures the geometry of that object using lasers, light, or X-rays and turns it into a digital mesh you can manipulate on a screen.

It’s kind of like taking a photograph, but instead of flat images, you get depth, curves, and textures. Think of it as the tech version of tracing something with pinpoint precision.

And here’s the fun part: there are a few different kinds of 3D scanners. Some use structured light—basically projecting patterns on the surface and recording how they distort—while others use laser triangulation or photogrammetry.

Each has its pros and quirks, depending on how detailed you want the final model to be and what you're scanning.

Skin and bones?

You might want a medical-grade scanner. A car bumper? You’ll probably be fine with a handheld 3D scanner.

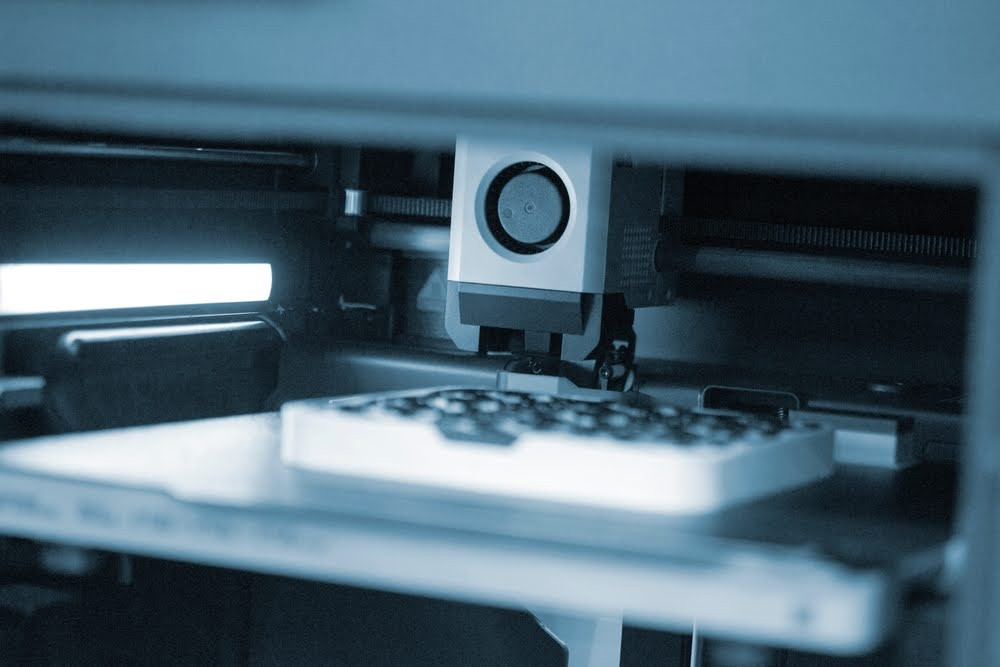

And 3D Printing? That’s the Opposite Direction

While 3D scanning captures an object, 3D printing creates one from nothing. Well, not from nothing, exactly.

It starts with a digital model and builds it layer by layer using materials like resin, plastic, metal, or even concrete.

Imagine your regular printer—but instead of printing flat ink on paper, it squeezes out physical material like a robotic hot glue gun with a mission.

There’s a stack of different printing technologies too—FDM (fused deposition modeling), SLA (stereolithography), SLS (selective laser sintering)… and yes, the acronyms get annoying.

But they all follow the same core concept: you feed the printer a 3D design, it slices it into layers, and the printer builds those layers up into a real, tangible object.

The possibilities are wild. Engineers print custom brackets and fixtures. Surgeons prep with models of patients’ organs.

Hobbyists create figurines of their pets (because, of course, they do). But printing can also be slow, depending on size and detail, and not all materials are created equal.

Two Sides of the Same Coin… Or Not?

Here's where things get juicy. People often think 3D scanning and 3D printing are part of one continuous process—like you scan a thing and print it, done.

And yes, they can work together like that. But they don’t always have to. And they certainly aren’t the same job.

3D scanning is typically used when you already have a physical object and want to replicate, study, or reverse-engineer it. You might scan an old machine part that no longer has CAD drawings.

Or scan someone’s foot for a custom orthotic. You could even use it for digital archiving—think ancient pottery being preserved for future generations.

On the flip side, 3D printing is often used when you have a digital design, whether made from scratch or based on a scan, and you need a physical prototype or final product.

Maybe you're testing out a new product design. Maybe you're creating replacement parts on-site in a remote location. Or maybe you’re just printing a cosplay helmet because Comic-Con’s next weekend.

Which Comes First—The Scan or the Print?

That depends. Sometimes it’s scan first, print later—like when replicating a real object. Other times, there’s no scanning involved at all—just good old-fashioned CAD design.

Engineers don’t scan every screw or panel they print. They build it from digital blueprints, tweaking the design in CAD before hitting print.

But in certain workflows, especially those involving customization or legacy parts, 3D scanning can feed directly into 3D printing. It’s like the perfect one-two punch: digitize, then materialize.

Still, this isn’t as automatic as it sounds. You can’t always scan something and instantly hit print. The scanned mesh usually needs cleaning, editing, or converting into a print-friendly format.

That might mean using mesh editing software or working with hybrid CAD systems that can handle organic and parametric geometry. Yeah—it can get nerdy fast.

Industries That Use Both (Because Efficiency Is King)

You’ll find this scan-print combo in industries where accuracy and speed matter. Think:

- Healthcare: Scan a patient’s limb, print a custom brace.

- Aerospace: Scan a damaged component, reverse-engineer it, then print a replacement.

- Automotive: Digitally capture a busted body panel, print a repair prototype.

- Entertainment: Ever wonder how game developers get real actors into games? Yep—3D scanning, then digital manipulation, maybe even a printed model for promo.

Some companies even use scanning to inspect the quality of 3D printed parts post-production. Talk about a full circle.

The Human Side of It All

Let’s step out of the tech for a sec. There's something kind of poetic about the relationship between scanning and printing.

One captures, the other creates. One preserves the past; the other builds the future. And when they meet? You get this powerful fusion of memory and possibility.

It’s not just about machines talking to machines—it’s humans using tools to understand and shape the world around them.

And you know what? Accessibility is growing. Ten years ago, 3D scanning cost a fortune and looked like something out of a NASA lab.

Now you’ve got apps that use your smartphone to scan faces or furniture (with varying success, sure, but still). Likewise, desktop 3D printers are more common in schools and garages than you’d expect.

As these technologies become more user-friendly and less intimidating, expect to see more crossover—more folks using both, blending workflows, and building better, faster, smarter.

A Few Things to Keep in Mind Before You Get Started

- Start with your goal. Need a digital version of something? Scanning. Need a physical version? Printing. Need both? Plan your workflow carefully.

- File formats matter. STL, OBJ, PLY, STEP… They all have different strengths. Don’t get lost in conversion hell.

- Hardware is only half the game. Good software and a bit of human judgment go a long way.

- Don’t expect miracles. Scans aren’t always perfect. Prints aren’t always flawless. Sometimes the tech needs a little human touch-up.

So… Which One’s “Better”?

That’s like asking whether a camera is better than a printer. Totally different jobs.

If your goal is to capture, analyze, or reproduce an existing object, 3D scanning is your friend. If you’re designing from scratch or manufacturing something new, 3D printing is probably where you’ll live.

And sometimes, the best answer is both—just not at the same time or in the same way.

Final Thought: The Real Power Comes in the Pairing

Here’s the thing - 3D scanning vs 3D printing doesn’t need to be a fight. When used together, they unlock all sorts of creative and practical workflows across industries.

And if you’re not sure where to begin or how to fit these tools into your workflow, we can help you figure it out.

From expert scanning solutions to tailored print systems, we’ve got the tools to help you connect the dots between idea and execution.

Got a project in mind? Let’s turn your scan into something tangible.