3D Scanner For Inspection

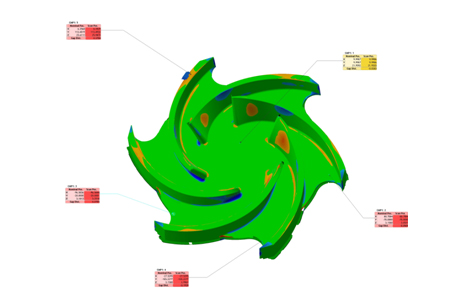

With the development of science and technology, and the improvement of manufacturing, a lot of classes A curved surface are appeared in parts of home appliance, aircrafts and vehicles. High accuracy is required from users, but it is hard to inspect such complex curved surfaces by traditional measurement tools, even if it can be inspected, the inspection accuracy is not high, especially in aspect of measurement of curved dimension, it cannot meet the requirement of time and operation difficulty in practice. At the time, various materials are used in modern manufacturing industry, such as soft and easy to deformed materials; it is not possible to inspect them by contact measurement method, so an alternative measurement method is necessary. 3D scanning inspection technology is a full size inspection technology; its basic method is to scan local or whole part of objects to be inspected, and get the 3D point clout data, and then compare with their CAD drawing, so a color picture of error code is made as an intuitive inspection report. Now, this 3d inspection technology has been more and more widely used, and is gradually accepted by manufacturing. industry.

Benefits

Minimize the error difference and save the time to the utmost :

This solution avoids manual error by carrying out CAD data inspection directly, which improves the inspection process efficiency.

Dramatic production efficiency improvement :

Professional inspection software could record all the steps and parameters.Batch inspection is as easy as single case inspection, because software could repeat the inspection procedure automatically. User can simply press one key to do one case or multi-case inspection job.

Smart inspection :

user can modify any step of the inspection process and the software shall update all related steps automatically. User has the right to modify till getting the best inspection result.

High accuracy :

repeatability is an important part of quality control process. Shining 3D full dimension inspection solution could help user realize this repeatibility easily. Its automation also minimizes the error difference from user to user.